Revit Guides

Data Management

ELI5

Wiring in Protected Escape Route

Compliance with fire safety regulations in Firefighting Cores directly affects life safety and emergency response.

This guide will help you meet the latest fire performance standards. With updates in BS 9991:2024 and BS 7671:2018+A2:2022 & May 2023 Corrigendum.

What ‘protected escape routes’ cover (Appendix 13):

“For safe escape… these routes are essentially fire sterile… the amount of combustibles in a protected escape route is strictly controlled.”

“For safe escape, it is essential that as well as being enclosed in a fire and smoke-resisting construction these routes are essentially fire sterile. In other words, ideally they should not contain combustible material which itself could cause a hazard to the escaping occupants. Thus the amount of combustibles in a protected escape route is strictly controlled.” BS 7671:2018+A2:2022, Appendix 13

Definitions

Escape route

“Escape route The route along which people can escape from any point in a building to a final exit.”

Reference: Approved Document B (Vol. 2), Appendix A – Key terms.Protected corridor / protected lobby

“Protected corridor/lobby A corridor or lobby that is adequately protected from fire in adjoining areas by fire resisting construction.”

Reference: Approved Document B (Vol. 2), Appendix A – Key terms.Protected stairway

“Protected stairway A stair that leads to a final exit to a place of safety and that is adequately enclosed with fire resisting construction. Included in the definition is any exit passageway between the foot of the stair and the final exit.”

Reference: Approved Document B (Vol. 2), Appendix A – Key terms.Firefighting lobby

“Firefighting lobby A protected lobby that provides access from a firefighting stair to the accommodation area and to any associated firefighting lift.”Firefighting stair

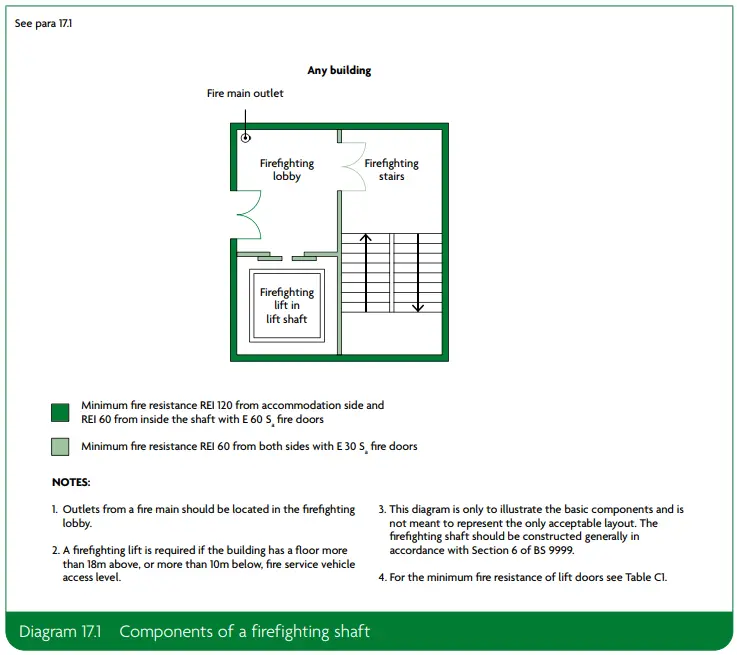

“Firefighting stair A protected stairway that connects to the accommodation area through only a firefighting lobby.”Firefighting shaft

“Firefighting shaft A protected enclosure that contains a firefighting stair, firefighting lobbies and, if provided, a firefighting lift together with its machine room.”

Reference: Approved Document B (Vol. 2), Appendix A – Key terms.Firefighting parts

“17.1 Facilities for fire and rescue, such as firefighting lifts, firefighting stairs and firefighting lobbies, are combined in protected firefighting shafts (Diagram 17.1). Section 8 gives guidance on the design and construction of protected shafts.”

Reference: Approved Document B (Vol. 2), clause 17.1.BS 7671 rule that interacts with the above (electrical in protected escape routes)

“422.2 Protected escape routes

Cables or other electrical equipment shall not be installed in a firefighting lobby, shaft or staircase of a protected escape route unless part of:

(i) an essential fire safety or related safety system

(ii) general needs lighting

(iii) socket-outlets provided for cleaning or maintenance.

NOTE 1: Guidance is provided in Appendix 13.

NOTE 2: Generally, this means cables in a firefighting lobby, shaft or staircase of a protected escape route should be limited to lighting and associated accessories, emergency lighting and fire detection and alarm systems, although cables for other safety systems may be necessary. Hospitals may have special requirements as detailed in Section 710.”

Reference: BS 7671:2018+A2:2022 – Corrigendum (May 2023), Regulation 422.2.

“A firefighting lobby is always part of a firefighting shaft; a protected lobby may or may not be, depending on the project fire strategy.”

Here’s the clean way to think about the relationships:

Firefighting lobby → always inside a firefighting shaft. It’s a type of protected lobby used to access the firefighting stair (and any associated firefighting lift). By definition, those elements together make up the firefighting shaft.

Protected lobby → general term. A protected lobby can either:

be just part of the building’s protected escape route (means of escape), or

be designated as the firefighting lobby for a firefighting stair/lift—in which case it is part of the firefighting shaft.

Same pattern for stairs:

Firefighting stair = a specific subset of protected stairway (and sits within the firefighting shaft).

Protected stairway = general; may or may not be a firefighting stair depending on the fire strategy.

Regulation 422.1.1 restricts the use of electrical equipment

Only cables meeting 422.2.1 may be installed in protected escape routes (flame-propagation per BS EN 60332 series and ≥ 60% light transmittance to BS EN 61034-2); where listed cable management systems are used, EN 60332-1-2 applies. Any such system must be classified non-flame-propagating to its product Standard and be of limited smoke production.

Cables or other electrical equipment shall not be installed in a firefighting lobby, shaft or staircase of a protected escape route unless part of:

(i) an essential fire safety or related safety system

(ii) general needs lighting

(iii) socket-outlets provided for cleaning or maintenance.

NOTE 1: Guidance is provided in Appendix 13.

NOTE 2: Generally, this means cables in a firefighting lobby, shaft or staircase of a protected escape route should be limited to lighting and associated accessories, emergency lighting and fire detection and alarm systems, although cables for other safety systems may be necessary. Hospitals may have special requirements as detailed in Section 710.BS 7671:2018+A2:2022 – Corrigendum (May 2023) 422.2 Protected escape routes

“Except for wiring systems meeting the requirements of Regulation 422.3.5, electrical equipment shall be restricted to that necessary to the use of the locations given in Regulation 422.1″ BS 7671:2018+A2:2022, 422.1.1

Passing-through Protected Escape Route

Can I pass through a Protected Escape Route?

Short answer:

• Firefighting shafts (firefighting stair/lobby/lift): only shaft-associated services may pass through or be contained within the shaft (ADB §17.9).

• Other protected escape routes (not part of a firefighting shaft): passing-through can be acceptable if you meet ADB Section 10 measures (e.g., ES dampers per Method 4) and BS 7671 Reg 422.2.1/521.10.202.

When permitted (non-firefighting protected lobbies/corridors/stairways): If the circuit is one of the BS 7671 Reg 422.2 categories (i) essential fire-/related-safety system, (ii) general needs lighting, (iii) cleaning/maintenance sockets) and all Reg 422.2.1 conditions are met, you may cross the protected lobby/corridor/stairway (not designated as firefighting). For firefighting shafts, ADB §17.9 still limits services to those associated with the shaft.

For a quick go/no-go and the exact checks to record, use the Permit-to-Route Checklist →

422.2 scope

“Cables or other electrical equipment shall not be installed in a firefighting lobby, shaft or staircase of a protected escape route unless part of: (i) an essential fire safety or related safety system (ii) general needs lighting (iii) socket-outlets provided for cleaning or maintenance.” (Notes point to Appendix 13 and clarify that this generally means lighting/emergency lighting/fire alarm, though other safety systems may be necessary.)

The May 2023 Corrigendum expressly states that Regulation 422.2 has been amended to clarify the scope of the provision.

Don’t use 422.3.5 to justify “general” pass-through here

422.3.5 is in 422.3 (locations with risks due to processed/stored materials – BE2). It allows pass-through wiring if strict conditions are met.

422.2 is a distinct subsection for protected escape routes. It prohibits installing cables/equipment there unless they’re part of the three listed categories.

The May 2023 Corrigendum was issued specifically to tighten/clarify this scope around firefighting lobbies, shafts and staircases, reinforcing that you cannot use 422.3.5 to justify pass-through in those protected areas.

Therefore, for 422.3 locations (e.g., BE2 areas), pass-through is allowed if 422.3.5 is fully met.

However, for protected escape routes covered by 422.2 (as clarified in May 2023), the specific prohibition takes precedence: only the listed systems are allowed; general pass-through is not.

This if further reinforced in Approved Document B Volume 2 (2019 edition incorporating 2020, 2022 and 2025 amendments, collated with 2026 and 2029 amendments). GOV.UK Assets clause 17.9

“Only services associated with the firefighting shaft, such as ventilation systems and lighting for the firefighting shaft, should pass through or be contained within the firefighting shaft.”

Key Requirements for Cables & Containment

Cables

- Good practice – not mandated by BS 7671 – Minimum: Cca-s1b,d1,a2, Preferred: B2ca-s1a,d1,a1.

- If the cable does not meet this classification, it must be enclosed in non-flame-propagating containment of limited smoke production to its product Standard, as listed in 422.2.1.

Supports & Fixings

- Provide metallic supports so the wiring system is not liable to premature collapse in fire; non-metallic fixings must not be the sole means of support (BS 7671 Reg 521.10.202). In practice it means EN 13501-1 Class A1 (fully non-combustible), or, as a minimum, surfaces achieving B-s3,d2 – e.g., steel brackets, supports, and anchors.

- Ferrous metal, e.g. steel, is deemed to be an example of a non-combustible material. (BS 7671:2018+A2:2022, Appendix 13)

- ❌ Not permitted as the sole means of support: Plastic clips or composite fixings, even if fire-resistant. (Supports/fixings to be metallic to meet 521.10.202)

Electrical Containment

- Cables must be installed in/on containment which is non-flame-propagating and of limited smoke to prevent fire spread.

- Fire-stopping must be applied at all penetrations to maintain fire integrity.

- Where conduit/ducting/trunking/busbar passes through a fire-resisting element and has an internal CSA > 710 mm², it shall be internally sealed per 527.2.3.

Summary of Compliance Options:

- Option 1: Use cables that meet Cca-s1b,d1,a2 classification.

- Option 2: Fully enclosed non-compliant cables in metallic containment systems (EN 61386/50085/etc.), (steel conduit/trunking).

BS EN 50085 Series for cable trunking and ducting systems BS EN 61386-1 for conduit systems

Practical Example: When using standard LV cables (which might not achieve Cca-s1b,d1,a2 ratings on their own), installing them in a steel conduit or non-flame-propagating containment of limited smoke production to its product Standard, as listed in 422.2.1. (certified per BS EN 61386-1 or BS EN 50085) can provide the necessary protection.

Understanding Cable Fire Classification

Under BS EN 13501-6 (the test standard used for cables under the Construction Products Regulation, CPR), cables are given a Euroclass rating such as:

Primary Euroclass (cables only – EN 13501-6)

| Class | Plain-English meaning (short) | Typical notes |

|---|---|---|

| Aca | No contribution to fire (effectively non-combustible) | Rare for cables |

| B1ca | Very limited contribution to fire | Stricter than B2ca |

| B2ca | Limited contribution to fire | Common high-spec class; tested incl. EN 50399 |

| Cca | Controlled contribution to fire | Tested incl. EN 50399 |

| Dca | Acceptable basic performance | Lower than Cca; limited flame spread |

| Eca | Basic flame propagation pass only | Entry level |

| Fca | No performance determined / fail Eca | Avoid for escape routes |

Higher up the list = better fire performance (Aca → B1ca → B2ca → Cca → …).

Optional modifiers you can append to the class

You’ll often see a full designation like B2ca-s1a,d1,a1.

| Suffix | What it controls | Options (best → worst) | Plain-English meaning |

|---|---|---|---|

| s | Smoke production | s1a, s1b, s2, s3 | s1a = very low smoke; s1b = low smoke; s2 = moderate; s3 = no limit |

| d | Flaming droplets/particles | d0, d1, d2 | d0 = none; d1 = none persisting >10 s; d2 = no requirement |

| a | Acidity/corrosivity of gases | a1, a2, a3 | a1 = very low; a2 = limited; a3 = no requirement |

By contrast, BS EN 13501-1 (more common for general building products like wall linings) uses classes A, B, C, D, E, F along with s and d indices, e.g., “B–s3,d2.”

Although the notations look similar, the specific tests and criteria differ slightly for cables versus other building materials. Roughly speaking:

- B2ca for cables is often considered on par or “better” than B–something for general construction products.

- s1a (very low smoke release) is better than s3 (higher smoke release).

- d1 (no sustained flaming droplets) is better than d2 (some flaming droplets allowed).

Hence B2ca–s1a,d1,a1 can be viewed as meeting or exceeding B–s3,d2 in practical fire-performance terms.

Metallic (non-combustible) supports Fixings

- EN 13501-1 A1 Definition: A1 materials are non-combustible and do not contribute to fire.

- Examples: Stainless steel brackets, trays, conduits, and concrete anchors.

- Not Compliant: Plastic or composite materials. ❌

Fire Classification for Cables

BS 7671 requires cable flame-prop limits and ≥60% light transmittance to BS EN 61034-2 when cables are permitted in protected escape routes. The “≥60%” aligns with CPR “s1b” (s1a ≥80%, s1b ≥60%–<80%).

Classes Cca / B2ca use the EN 50399 large-scale flame spread & heat release test (on top of EN 60332-1-2), giving a robust flame-prop baseline that dovetails with the Wiring Regs’ “non-flame-propagating” intent.

d1 (limited flaming droplets) and a2/a1 (limited acidity) are not explicitly set in BS 7671, but they’re widely adopted in UK practice for escape routes because they support tenability (reduced burning droplets/corrosive smoke). These attributes are part of the EN 13501-6 scheme.

Cable classification example:

Minimum: Cca-s1b,d1,a2:

- Cca: limited fire growth/heat release and controlled flame spread under EN 50399.

- s1b: low smoke– light transmittance ≥60% and <80% (the s1 family is the most stringent for smoke; s1a ≥80%).

- d1: Limited flaming droplets/particles – none persisting >10 s. (d0 = none at all; d2 = no requirement)

- a2: Limited (intermediate) acidity of combustion gases (less stringent than a1, more than a3); assessed to EN 60754-2 within the EN 13501-6 scheme.

Preferred: B2ca-s1a,d1,a1

- B2ca: Stricter cable class than Cca (very limited contribution to fire growth/heat release) per EN 50399.

- s1a: Very low smoke– light transmittance ≥80%

- d1: Limited flaming droplets/particles – none persisting >10 s.

- a1: Very low acidity/corrosivity of combustion gases.

Summary:

✅ Unenclosed routing in FF stairs/lobbies/shafts is acceptable only where:

– the circuit is permitted by 422.2;

– the cable satisfies BS 7671 fire-performance for protected escape routes (flame propagation and ≥ 60% light transmittance to BS EN 61034-2); and

– the fire strategy explicitly accepts exposed routing (e.g., bare MICC or “minimal cable in fully-sealed ferrous conduit” per Appendix 13 guidance).

✅ Containment: where unenclosed routing isn’t justified, use metallic (non-combustible) containment in these cores by default. Non-metallic systems may be used only if classified non-flame-propagating to their product standard and accepted by the fire strategy.

✅ Supports/fixings: provide metallic supports to prevent premature collapse (no plastic as the sole means).

Cable Classification (FP600s example)

Prysmian FP600S (BS 7846-F120) meets the latest CPR Euroclass rating:

- B2ca–s1a, d1, a1, (better than B-s3, d2).

- B2ca: Higher fire resistance than B-s3.

- s1a: Very low smoke production (better than s3).

- d1: Minimal flaming droplets (better than d2).

Compliance with BS 9991:2024

- BS 9991:2024 deals with fire safety in the design, management, and use of residential buildings. Where it references reaction-to-fire performance of cables (for instance, in escape routes or critical circuits), a B–s3,d2 or better classification is often cited.

- Because FP600S is classified as B2ca–s1a,d1,a1, it satisfies a higher standard of reaction-to-fire than B–s3,d2.

- As long as the cable is installed in accordance with the rest of BS 9991’s guidance (e.g., containment, fire-stopping around penetrations, circuit design, etc.), FP600S would be fully acceptable.

FP600S exceeds the fire performance requirements and is fully compliant with BS 9991:2024 when installed correctly.

Compilance with BS 8519 Category 3

Power cables: 120 min survival time when tested in accordance with BS 8491.

Control cables: 120 min survival time when tested in accordance with BS EN 50200:2015, and 120 min survival time when tested in accordance with BS 8434-2 (core sizes up to and including 4 mm² CSA) and Annex D (core sizes up to and including 4 mm² CSA), excluding 3-phase power circuits.

Other Multicore SWA Options

If, for some reason, FP600S is not suitable (cost, availability, or otherwise), you can look at alternative BS 7846-F120 or fire-rated SWA cables from other manufacturers – many now offer B2ca–s1,d1 (or s1a,d1) ratings. Examples include:

- Draka Firetuf Powerplus (sometimes listed as B2ca–s1,d1,a1)

- Nexans Fire-Performance Armoured cables meeting BS 7846-F120 & CPR B2ca

Always confirm with the manufacturer’s datasheet or DoP (Declaration of Performance) that the specific drum/batch of cable has the required CPR rating.

Installation Best Practices for Fire Compliance

To achieve full compliance, correct installation is essential:

- Keep protected routes “essentially fire sterile” and minimise combustible load.

In firefighting lobbies, shafts or staircases of a protected escape route, you may only install equipment that is part of (i) an essential fire-safety or related-safety system, (ii) general-needs lighting, or (iii) cleaning/maintenance sockets. Anything else (e.g., general distribution boards) is out.

If (and only if) such permitted switchgear/controlgear must be in an escape route, it must be accessible only to authorised persons and enclosed in a cabinet or enclosure of non-combustible or not readily combustible material. Items installed to facilitate evacuation such as fire-alarm call points are excluded from this enclosure requirement.

- Use A1-rated steel supports (brackets, fixings, and hangers).

- Ensure cables are installed in steel containment if they do not meet Cca-s1b,d1,a2.

- Coordinate with other MEP services to ensure all materials in the fire core meet fire classification requirements.

Fire-Stopping Considerations

- Seal all cable penetrations in fire cores with approved fire-rated seals or intumescent collars.

- Ensure that any joints or terminations in high-risk areas are enclosed in a non-flame-propagating containment of limited smoke production to its product Standard, as listed in 422.2.1.

- Where conduit/ducting/trunking/busbar passes through a fire-resisting element and has an internal CSA > 710 mm², it shall be internally sealed per 527.2.3.

- Cables installed in a fire resisting enclosure are deemed to be outside the protected escape route,” and include the sealing duties and performance criteria (compatibility, movement, stability) from Appendix 13.

Permit-to-Route checklist (FF lobby / shaft / staircase of a protected escape route)

| # | Check item | Verify / Acceptance criteria | BS 7671/ADB reference |

|---|---|---|---|

| 1 | Is the area a component of a firefighting shaft | Confirm via the building’s fire strategy / plans / FRA; if unclear, get expert advice. | Approved Document B (Vol. 2), Clause 17.1 & 17.9 |

| 2 | Is this really a protected escape route? | Confirm via the building’s fire strategy / plans / FRA; if unclear, get expert advice. | Appendix 13 (“Protected escape routes”) |

| 3 | Is the purpose allowed? | Only three categories permitted in these spaces: (i) essential fire-safety or related-safety systems, (ii) general-needs lighting, (iii) cleaning/maintenance sockets. | 422.2 (Corrigendum May 2023) |

| 4 | Interpreting “essential” | Typically: lighting & accessories, emergency lighting, fire detection & alarm; other safety systems may be necessary. | 422.2 Note 2 (Corrigendum May 2023) |

| 5 | Cable fire performance | Cables here shall meet (i) flame-prop limits (BS EN 60332 series¹) and (ii) ≥60% light transmittance to BS EN 61034-2. | 422.2.1(i)–(ii) |

| 6 | Routing discipline | Keep runs as short as practicable; do not install within arm’s reach unless protected against likely mechanical damage during evacuation. | 422.2.1 (mid-para) |

| 7 | Containment type & smoke | If you use cable management, it must be non-flame-propagating and of limited smoke production; permitted types: EN 61386 conduit, EN 50085 trunking/ducting, EN 61537 tray/ladder, EN 61534 powertrack. | 422.2.1(iii)–(vi) |

| 8 | CPR note | Non-fire-resisting cables must satisfy CPR reaction-to-fire; CPR does not set requirements for fire-resisting cables in 560.8. | 422.2.1 Note 1 |

| 9 | Safety-circuit fire resistance | If the circuit is a safety circuit, provide fire resistance for the required time (or ≥1 h if none specified). | 422.2.1 (final para) → 560.8 |

| 10 | Supports & fixings | Wiring systems must not be liable to premature collapse in fire → metallic supports; plastics must not be the sole means. | 521.10.202 (and notes) |

| 11 | Switchgear in escape routes | If installed here: authorised access only and enclosed in a non-combustible / not readily combustible cabinet/enclosure. | 422.2.2 |

| 12 | Mechanical protection within arm’s reach | If any permitted cable/kit is within arm’s reach on the escape route, provide protection against likely mechanical damage during evacuation (e.g., robust metallic conduit/trunking or routing out of reach). | 422.2.1 (mid-para) |

| 13 | FR enclosures | Cables in a fire-resisting enclosure are deemed outside the protected escape route. | Appendix 13 (“Cables in a fire-resisting enclosure…”) |

| 14 | Fire-stopping & internal sealing | Restore FR where penetrations occur (527.2.1). If containment internal CSA > 710 mm², internally seal per 527.2.3. | 527.2.1, 527.2.2, 527.2.3; Appx 13 (710 mm² trigger) |

| 15 | Lift wells / flue-like openings | Do not install safety-service circuits in lift wells or flue-like openings, except FRS lift supply cables (and lifts with special requirements). | 560.7.8 |

| 16 | Segregation & selectivity | Separate safety-service cables from others (distance/barriers). Choose OCPDs so a fault in one circuit doesn’t impair safety circuits. | 560.7.7 (segregation); 560.7.4 (selectivity) |

| 17 | Safety-services documentation | Maintain drawings/diagrams showing equipment/DB locations and particulars; keep at or near the DB. | 560.7.9–560.7.12 |

| 18 | Healthcare (if applicable) | In healthcare facilities, cables/equipment may be in a protected escape route where the facility complies with HTM/healthcare fire guidance and it’s documented in the fire strategy. | 710.422.2.201 (Corrigendum May 2023) |

¹ Reg 422.2.1 says where cable management systems (iii)/(iv) are used, the cables shall conform to BS EN 60332-1-2.

Final Thoughts

With stricter fire regulations under BS 9991:2024, electrical installations within firefighting cores and escape routes must comply with enhanced fire classification requirements for cables, fixings, and containment.

Using BS 7846-F120 compliant cables like FP600S and ensuring correct installation methods will help meet compliance while maintaining fire safety in high-risk buildings.

References

BS 9991:2024 – Fire safety in residential buildings.

BS 7671:2018+A2:2022 – Requirements for Electrical Installations.

BS EN 60332-1-2 – Test for Vertical Flame Propagation.

BS EN 50085 & BS EN 61386-1 – Cable Trunking and Conduit Systems.

BS 7846-F120 – Fire-Resistant Armoured Power Cables.

- BS 8519:2020 For fire-resistant power and control cables in life safety systems.

This guide is designed as a practical resource to help you achieve the highest fire safety standards in electrical installations.

Stay safe and compliant

4 responses

Thanks for sharing. This is highly informative.

I guess similar selection would definitely be applicable for critical systems designing and installation.

Exactly, the requirements for critical systems are very similar, if not the same. In the end Life safety is a critical system. There could be just different project requirements over and above whats required by regulations (code). T

Hey mate,

Good bit of research here, when you say wire mesh is classed a “cable tray” – where specifically is that worded. I’m concerned that OFRs interpretation of 9991s term “tray” would be a product called tray, I don’t think they would understand the nuance.

On Woolwich , as part of the gap analysis, the client decided not to go down the route of 9991 compliance for communal corridors.

Josh

‘Cable Basket’ (Wire-mesh tray) is an installation method recognised in BS 7671 (Appendix 4 Table 4A2 ‘Wire mesh tray’).

The key requirement is that the containment shall be ‘non-flame propagating’

BS 7671 requires cable tray/ladder systems used in protected escape routes to be non-flame-propagating to BS EN 61537 (Reg. 422.2.1).

Therefore, a compliant wire-mesh tray to BS EN 61537 with metallic fire-resistant fixings (Reg. 521.10.202) meets the intent for ‘tray’.

Below screenshot of Legrand ‘steel wire cable tray’ – ‘basket’ tested to IEC 61537 – the technical content is the same as BS EN 61537

Best,